When it comes to the topic of alignment,

let’s accept the fact that “coupling alignment”

is a misnomer. We are not concerned

about bringing coupling halves into alignment—

we’re only interested in ensuring that the

shafts of the pump and its driver will rotate on a

common axis. If the shafts are not coaxial, the

resulting moments will increase the forces on the

pump shaft and bearings, causing accelerated wear

and premature failure.

In most installations, it’s accepted that perfect

shaft alignment is unlikely throughout the operating

cycle. In such conditions, the coupling selection

should be able to accommodate the maximum

amount of the misalignment anticipated. This

should be confirmed with the coupling supplier, as

even flexible couplings have limitations that are

often ignored, resulting in premature bearing failure

and unreliable operation.

Sunday, July 4, 2010

Shaft Offset and Angularity

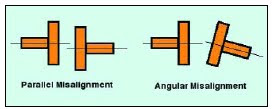

Alignment occurs when two lines that are

superimposed on each other form a single line.

Misalignment is a measure of how far apart the two

lines are away from forming that single line. The

two lines we’re concerned with here are the centerlines

of the pump shaft and the driver shaft. In one

condition, the two lines can be parallel with each

other, but at a constant distance apart. This is

referred to as offset or parallel misalignment. In the

other, one line will be at an angle to the other. This

is referred to as angular misalignment.

Parallel misalignment can be considered as the

distance between the driver shaft centerline and the

pump shaft centerline at any given point along the

length—and it can happen in any plane.

Consequently, it is worthwhile to take the necessary

measurements on the top and on the bottom for

vertical offset, and also on each side for the horizontal

offset.

Angular misalignment refers to the difference

in slope of the two shafts. If the pump, base and

foundation have been properly installed, the shaft

centerline of the pump can be considered as level,

and therefore, as the reference or datum line. The

slope of the driver shaft can be calculated by determining

the offset measurement at two different

points, subtracting one from the other, and dividing

the result by the axial distance between the two

points. (See Figure 2.) This misalignment should be

measured and calculated in both the vertical and

horizontal planes

superimposed on each other form a single line.

Misalignment is a measure of how far apart the two

lines are away from forming that single line. The

two lines we’re concerned with here are the centerlines

of the pump shaft and the driver shaft. In one

condition, the two lines can be parallel with each

other, but at a constant distance apart. This is

referred to as offset or parallel misalignment. In the

other, one line will be at an angle to the other. This

is referred to as angular misalignment.

Parallel misalignment can be considered as the

distance between the driver shaft centerline and the

pump shaft centerline at any given point along the

length—and it can happen in any plane.

Consequently, it is worthwhile to take the necessary

measurements on the top and on the bottom for

vertical offset, and also on each side for the horizontal

offset.

Angular misalignment refers to the difference

in slope of the two shafts. If the pump, base and

foundation have been properly installed, the shaft

centerline of the pump can be considered as level,

and therefore, as the reference or datum line. The

slope of the driver shaft can be calculated by determining

the offset measurement at two different

points, subtracting one from the other, and dividing

the result by the axial distance between the two

points. (See Figure 2.) This misalignment should be

measured and calculated in both the vertical and

horizontal planes

High Temperature Corrections

When a foot-mounted process pump must

operate at elevated temperatures, some adjustment

will be necessary to allow for the thermal growth

that takes place between the cold condition and the

high operating temperatures. As the pump heats up,

the shaft centerline will be moved up, creating an

offset with the motor shaft.

One method of handling this situation is to

misalign the motor by the amount of growth anticipated

from the pump prior to starting it up. Most

pump manufacturers can provide the cold setting

figures corresponding to the higher operating temperatures.

This will require the pump and motor

shafts to run in a misaligned setting until the pump

is fully up to temperature, by which time, the

expansion of the pump will raise it into position to

align with the motor.

A second method is to start the pump and

motor following a cold alignment, without any

adjustment. As the pump heats up and expands, it

will gradually move up, out of alignment with the

motor. When the pump is fully up to temperature,

the unit is stopped and hot alignment takes place.

For both of these methods, a flexible coupling,

capable of accommodating the total amount of

anticipated misalignment, will be required.

operate at elevated temperatures, some adjustment

will be necessary to allow for the thermal growth

that takes place between the cold condition and the

high operating temperatures. As the pump heats up,

the shaft centerline will be moved up, creating an

offset with the motor shaft.

One method of handling this situation is to

misalign the motor by the amount of growth anticipated

from the pump prior to starting it up. Most

pump manufacturers can provide the cold setting

figures corresponding to the higher operating temperatures.

This will require the pump and motor

shafts to run in a misaligned setting until the pump

is fully up to temperature, by which time, the

expansion of the pump will raise it into position to

align with the motor.

A second method is to start the pump and

motor following a cold alignment, without any

adjustment. As the pump heats up and expands, it

will gradually move up, out of alignment with the

motor. When the pump is fully up to temperature,

the unit is stopped and hot alignment takes place.

For both of these methods, a flexible coupling,

capable of accommodating the total amount of

anticipated misalignment, will be required.

Typical Acceptance Values

Bringing the motor shaft into alignment with

the pump shaft usually involves moving the front

and rear feet of the motor, vertically and horizontally,

until the shafts are aligned within acceptable

tolerances.

In addition to their dependency on data such as

speed of rotation, horsepower, spacer length, shaft

size, etc., acceptable alignment tolerances also

depend, to a large extent, on the level of reliability

the pump user expects. Accordingly, every end user

should develop acceptance levels that provide their

particular desired outcomes.

The tolerances in Table 1 are not intended as

definitive values, but can be used as a starting point

for developing tolerances that will be specific to an

individual company or equipment. They represent

the maximum allowable deviation from the desired

value, whether that value is zero or a targeted misalignment

to allow for thermal growth of the equipment.

the pump shaft usually involves moving the front

and rear feet of the motor, vertically and horizontally,

until the shafts are aligned within acceptable

tolerances.

In addition to their dependency on data such as

speed of rotation, horsepower, spacer length, shaft

size, etc., acceptable alignment tolerances also

depend, to a large extent, on the level of reliability

the pump user expects. Accordingly, every end user

should develop acceptance levels that provide their

particular desired outcomes.

The tolerances in Table 1 are not intended as

definitive values, but can be used as a starting point

for developing tolerances that will be specific to an

individual company or equipment. They represent

the maximum allowable deviation from the desired

value, whether that value is zero or a targeted misalignment

to allow for thermal growth of the equipment.

Runout

With the coupling disconnected, mount the

magnetic base of the dial indicator to the motor

half coupling, position the indicator on the pump

half coupling and center the indicator plunger.

Rotate the pump shaft until the dial indicator

reaches a maximum travel, then zero the dial indicator.

Rotate the pump shaft again until the dial

indicator reaches a maximum value. This shows the

amount of runout.

If the runout on the pump side is in excess of

the acceptable limit of 0.002”, the pump shaft runout

should be checked as above, except with the dial

indicator applied to the shaft. If the shaft runout is

0.001” or less, the shaft can be considered acceptable,

but the coupling is eccentric. If, however, the

shaft runout is greater than 0.001”, the shaft should

be straightened. By switching the position of the

dial indicator, the driver shaft can be checked in the

same manner with the same limitations.

magnetic base of the dial indicator to the motor

half coupling, position the indicator on the pump

half coupling and center the indicator plunger.

Rotate the pump shaft until the dial indicator

reaches a maximum travel, then zero the dial indicator.

Rotate the pump shaft again until the dial

indicator reaches a maximum value. This shows the

amount of runout.

If the runout on the pump side is in excess of

the acceptable limit of 0.002”, the pump shaft runout

should be checked as above, except with the dial

indicator applied to the shaft. If the shaft runout is

0.001” or less, the shaft can be considered acceptable,

but the coupling is eccentric. If, however, the

shaft runout is greater than 0.001”, the shaft should

be straightened. By switching the position of the

dial indicator, the driver shaft can be checked in the

same manner with the same limitations.

Soft Foot

To check for soft foot prior to alignment, when

there are no shims under the motor feet, start by

trying to fit a 0.005” shim under each foot. If the

shim fits under a foot, make up the gap by gradually

increasing the shim thickness until a tight fit is

achieved. If shims are already in place, ensure that

there are no more than four of them in any one

location. If there are, consolidate them by using

thicker shims. Check at each foot for loose shims

and make up the gap by gradually increasing shim

thickness until a tight fit is achieved at all feet.

A final soft-foot check should be performed

only after any vertical angular misalignment has

been corrected. When that has been achieved,

mount the dial indicator to contact the foot to be

checked and set the indicator to zero. Loosen the

hold-down bolt on that foot and record the dial

indicator reading, then retighten the hold-down

bolt. Repeat this process with all four feet.

Soft-foot conditions in excess of 0.002” should

be corrected by adding shims to the foot with the

largest soft-foot value. Note that excess shims will

result in increased soft foot at the other feet. Check

other feet and make any necessary corrections.

But, Let’s Be Practical. While dial indicators are

still a viable method of establishing shaft alignment,

laser alignment systems are now providing increased

accuracy that reduce maintenance costs

while improving reliability. In today’s workplace,

where fewer people are expected to do more, these

systems reduce the time it takes to achieve a high

level of accuracy—and do so without the need for

mathematical graphing and calculating expertise.

there are no shims under the motor feet, start by

trying to fit a 0.005” shim under each foot. If the

shim fits under a foot, make up the gap by gradually

increasing the shim thickness until a tight fit is

achieved. If shims are already in place, ensure that

there are no more than four of them in any one

location. If there are, consolidate them by using

thicker shims. Check at each foot for loose shims

and make up the gap by gradually increasing shim

thickness until a tight fit is achieved at all feet.

A final soft-foot check should be performed

only after any vertical angular misalignment has

been corrected. When that has been achieved,

mount the dial indicator to contact the foot to be

checked and set the indicator to zero. Loosen the

hold-down bolt on that foot and record the dial

indicator reading, then retighten the hold-down

bolt. Repeat this process with all four feet.

Soft-foot conditions in excess of 0.002” should

be corrected by adding shims to the foot with the

largest soft-foot value. Note that excess shims will

result in increased soft foot at the other feet. Check

other feet and make any necessary corrections.

But, Let’s Be Practical. While dial indicators are

still a viable method of establishing shaft alignment,

laser alignment systems are now providing increased

accuracy that reduce maintenance costs

while improving reliability. In today’s workplace,

where fewer people are expected to do more, these

systems reduce the time it takes to achieve a high

level of accuracy—and do so without the need for

mathematical graphing and calculating expertise.

Subscribe to:

Comments (Atom)